IRON SHELL PAVILION

Location Tafresh, Iran

Date 2016

Employer Azad University of Tafresh

Sponsor Azad University of Tafresh

IRON SHELL PAVILION

Tafresh, Iran | 2016

Designers: MEHRDAD AZIZKHANI, ALI NAKHAEI

In 2016, we were offered a workshop on “Computational design and digital fabrication” at Tafresh Azad University. This workshop was held in two stages to acquaint architecture students with computational design. The first phase of the workshop was held for three days with the CDX#1 title in August 2016 about the basics of computational design. One week later, the second phase of the workshop ended with the construction of a project of human scale size.

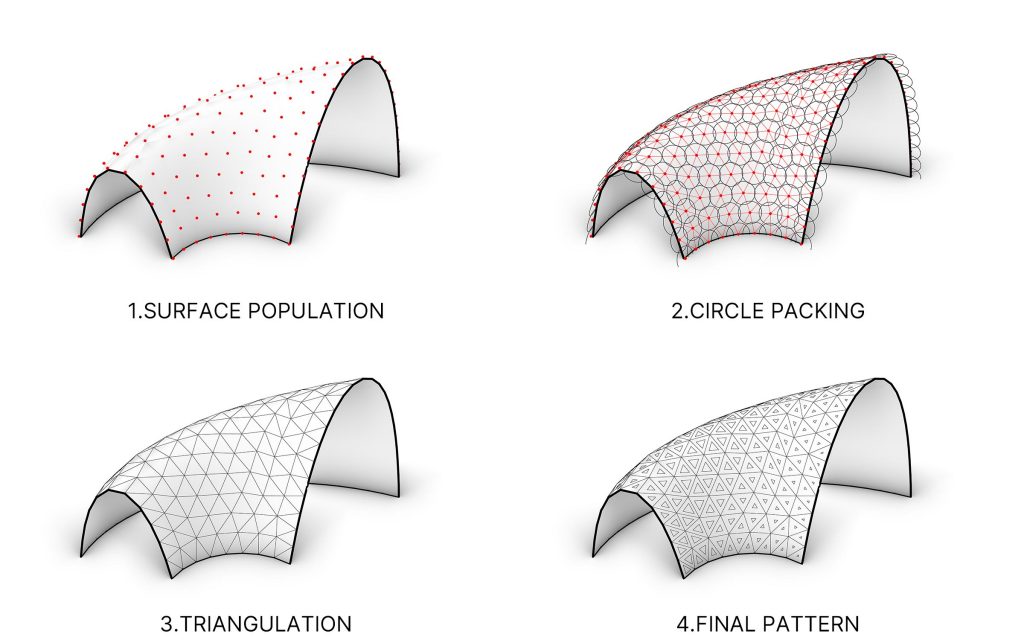

The form of this project was selected by the fabrication team members according to the prototypes made in the first stage of the workshop. This form was obtained by simulating a catenary structure in grasshopper software. Random points were generated on the resulting shell and the distance between points was optimized by the circle pack algorithm. Finally, the Delaunay diagram of the points draw and the details of the connections were added to each of the obtained triangles.

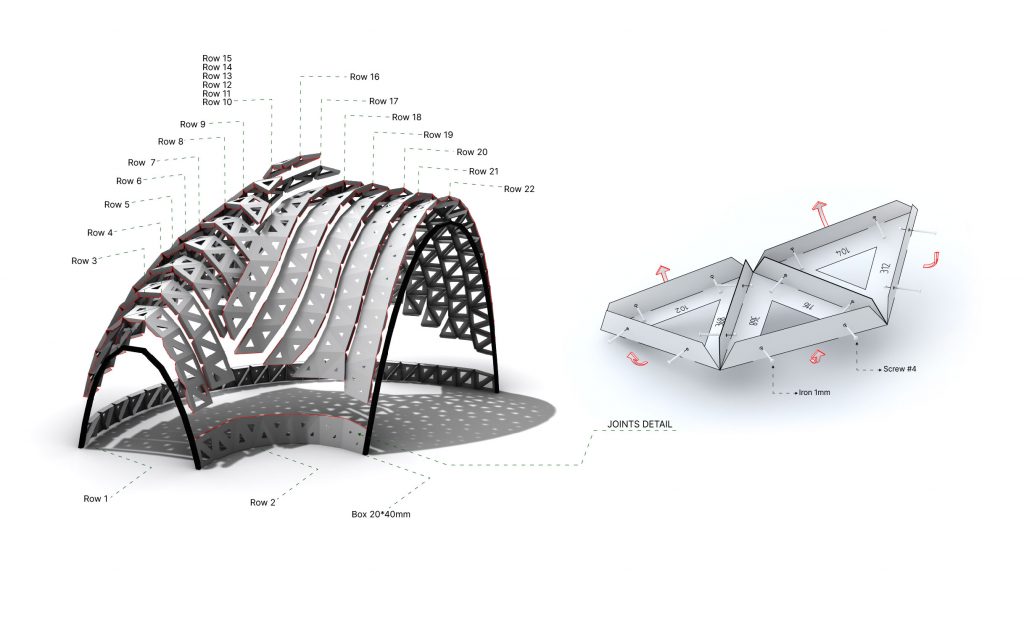

Then, structural analysis were performed on the project by millipede plugin, and how to connect to the ground was determined.

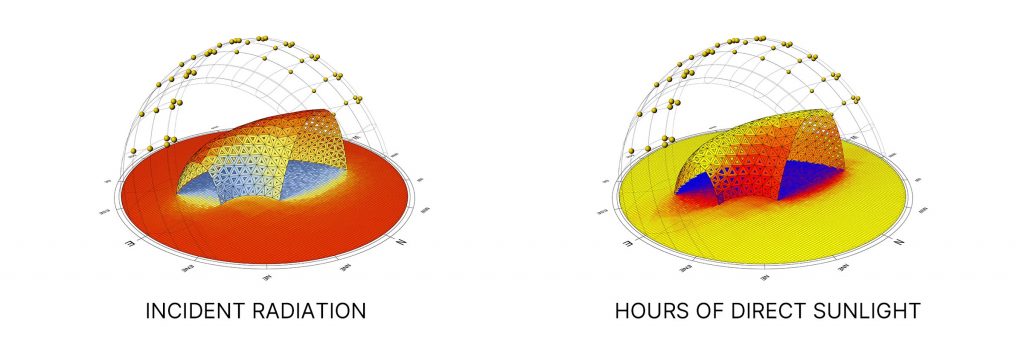

In the next step, climatic calculations were performed on the project, and holes were added to the panels to both reduce the wind load and let pass some of the sunlight, and create more beauty under the shell.

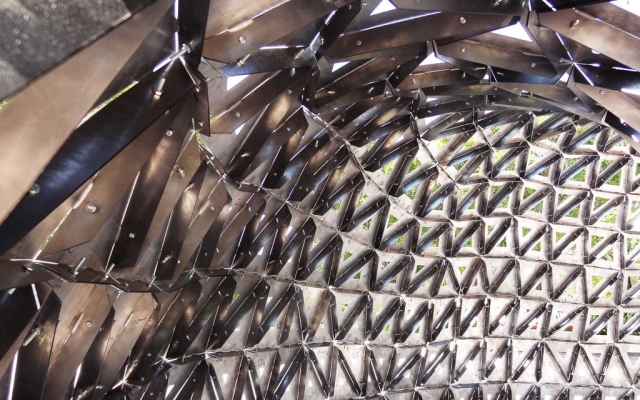

One millimeter thick steel sheet was used to make the shell. The edges of each panel were bent inwards and attached to adjacent parts. A total of 403 pieces were produced and 2 bolts were used for each edge, for a total of 900 bolts.

At the ground joints, the bent edges of the panels were welded and fastened to steel rebars previously installed in the ground. The process designed to build was that first all the panels were coded based on their adjacent components and then grouped into specific rows, one-row panels connected, and then moved to the execution site. We were then screwed to the fixed part on the ground. In the same way, the next rows were added to the previous rows. The two outer edges of the pavilion were restrained using two arches made of steel profiles with a square cross-section of 20 by 20 mm.